Craftsmanship

- Top page

- Craftsmanship

- Kitano Hamono Craftsmen

Craftsmanship in pursuit of tools that fit comfortably in the hand

Products made by Kitano Hamono, such as leather skivers, ground spatulas, putty spatulas and smoothing brushes are, we are told, tools that craftsmen feel like they have used for years when first holding them. And that’s just what we have in mind when making them.

Kitano Hamono listens to the opinions of the craftsmen who use our tools and is constantly reviewing ways to improve the forms of our tools so that they are more user-friendly and effective.

Craftsmanship in pursuit of user-friendliness

Occasionally, the chairman of Kitano Hamono shows up at a craftsman’s place of work. This allows him to speak to craftsmen and see for himself how they use our tools.

He then brings back any issues that he comes across, and grapples with such issues with craftsmen who occasionally work at the factory. This is a meeting of minds to discover the best way of producing good tools from both sides.

A never-give up attitude, based on a concept of “making ideas a reality”, is embodied in each and every one of Kitano Hamono’s products.

Craftsmanship with an emphasis on “hand-made”

Kitano Hamono products place an emphasis on “hand-made” in both our Japanese and Chinese factories. Even when we say “hand-made”, machines are used somewhere in the process, so we cannot say “100% hand-made”.

At Kitano Hamono, we don’t lose that attention to detail even when using machines. A preciseness measured in units of millimeters when it comes to product details has produced Kitano Hamono’s “craftsmen”. We are proud to think that we have achieved this through an emphasis on “hand-made” that is not possible with mass-production.

Integrated in-house craftsmanship

Most of our products are manufactured in-house. This is because we want to have full control over the products we deliver to craftsmen.

Of course, there are some things that we cannot complete in-house, so we entrust those jobs to associated companies. However, we thoroughly check all final products ourselves before delivering them to craftsmen.

Craftsmanship right up to the finishing touch

Kitano Hamono’s attention to detail extends right up to giving the finishing touches to products, ranging from the printing of silk screens on handles to finishing the surface of blades and hammering in screws.

To let you into a secret, the printing of silk screens was first done by an amateur! (However, we soon also mastered this job to a professional level.)

We are meticulously professional from applying the finishing touches to a product and then dispatching that product.

In pursuit of tools easy to use for development and innovation

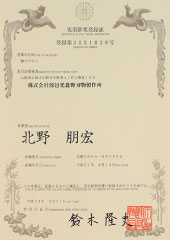

The Kitano Hamono chairman’s ideas are really astounding and utility models based on these ideas have increased in no time.

Moreover, the chairman really can’t say “no can do” to craftsmen. “How about doing so-and-so” he says, coming up with a new idea, and with that, he returns to the company.

Through repeated trial-and-error, and sometimes over many years, he never gives up.

Running out of patience, I will say “OK. Let’s give it a go.” But that smile on his face when something works out, is something special. That is really pleasing.

Undoubtedly, the chairman would love to see that same look on the faces of craftsmen. I always think, “glad I made it now”, when thanked by that craftsman.

Staff that support this meticulous craftsmanship

This is the staff of Minamoto-no-Muramitsu Kitano Hamono. All the workers pictured here protect the traditions and techniques of the company.

There is something that we are particularly meticulous about when manufacturing products. That is ensuring that craftsmen can use our products for an eternity. And that our products will improve the efficiency of users. The third is to put a smile on customers’ faces.

Therefore, rather than thinking about “making” products, we think about “creating” them. The staff at Minamoto-no-Muramitsu Kitano Hamono are meticulous about each and every product.